Phone: 8613421351153

Steel deck conforming to European and American standards

Steel decking is used in many applications, but is particularly well suited to roofing and flooring. For more than 20 years, Solideck has been manufacturing many different types of deck, including roof deck, floor deck, composite floor deck. Following are the details you’ll need about any of our products. You’ll get the answers that will help make your next project a success.

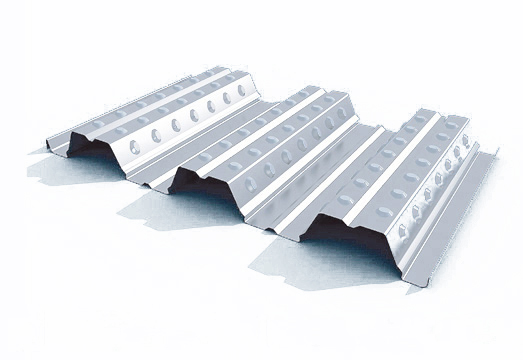

Types Of Steel Decking Profiles

Solideck suppliers will offer three basic types of steel decking.

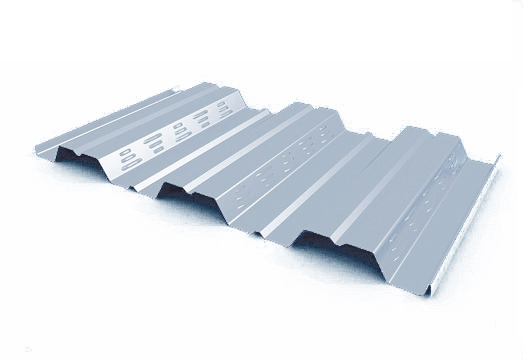

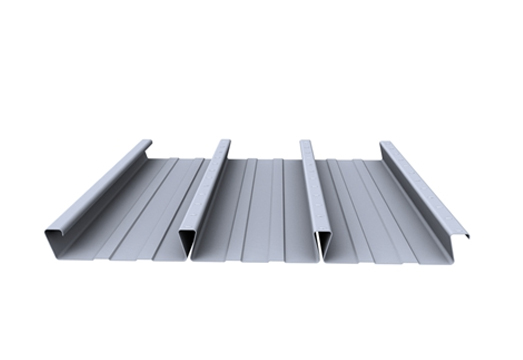

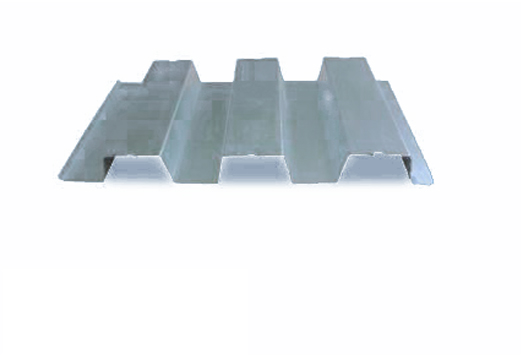

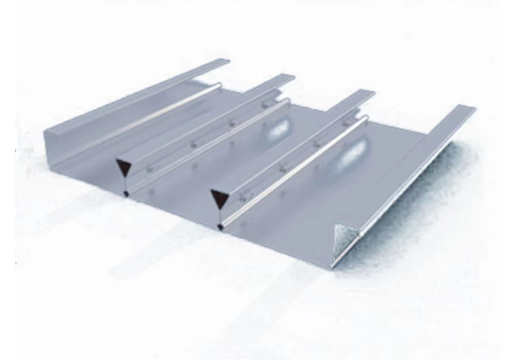

- Roof decking: Structural steel deck that’s used for roofs, canopies, walls, and gates

- Steel floor decking: Solideck that’s used for structural concrete. It has embossments in the flutes of the steel decking that will bond with the concrete. This creates a composite deck system.

- Steel form decking: These panels are smooth and don’t have embossments along the interior flutes of the decking. It’s not a composite floor deck. It’s only purpose is to be used as a stay in place form that will support the weight of the concrete while the concrete slab cures.

- Sandwich: This is a patented metal deck system that was created by Verco and Vulcraft. It’s not so much a style of steel decking, but refers to the required side lap connection. Punchlok II is crimped with a special Punchlok II tool. This allows for the use of lighter gauge metal deck and creates higher diaphragm shear values.

Our product

why to choose steel deck of Solideck

metal decking Industry experts

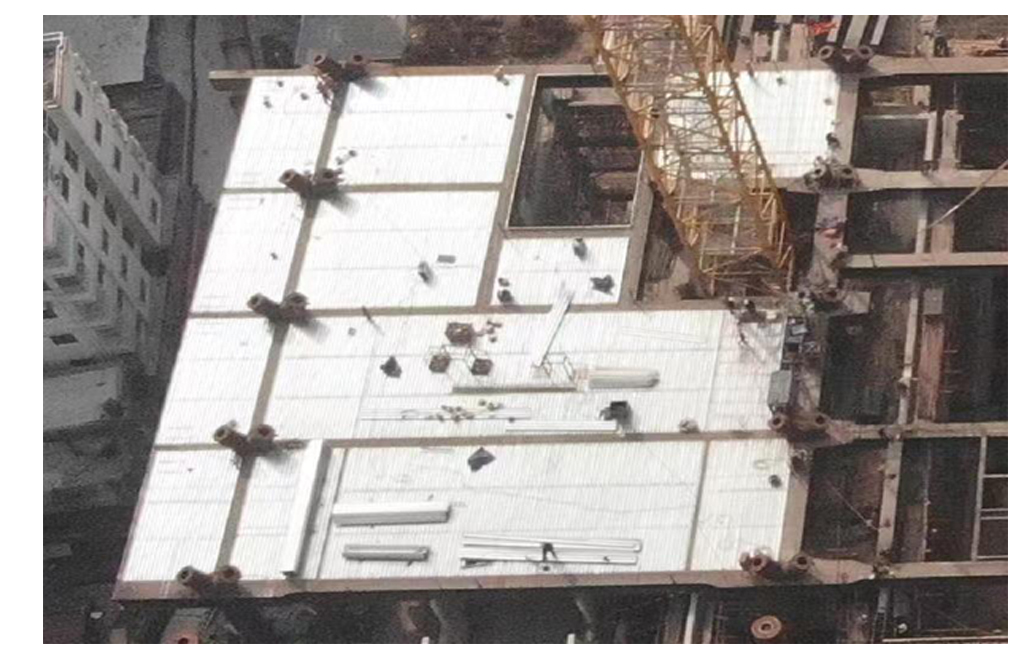

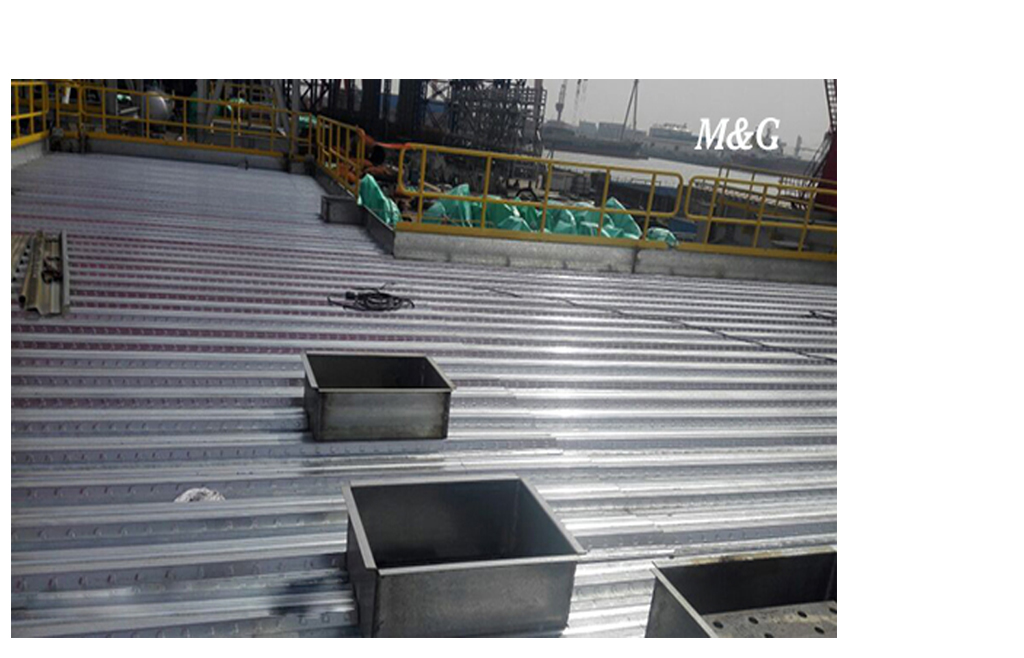

Established in the year 2006, SoliDeck stays now in a 5000 square meters workshop with 24 employees and 10-engineer team to focus on the innovation of Steel roof decks,composite deck,form deck.During the 16 years, Solideck has done more than 100 projects, including super high-rise buildings, factories, hospitals, and cultural facilities. There are transportation facilities, etc. We have accumulated valuable experience in this industry, which is also the reason why most customers choose us.

Assiduous pursuit of steel deck technology

As the founder of the company, Mr. Toy has been working in this field for more than 20 years. He has experienced the entire development process of the steel deck industry in China. He is not only very familiar with GB, but also with American standards, European standards. and have given technical lectures on steel decks in major design institutes

Dependable & Reliable Quality Assurance

Solideck is very strict with product quality. Since the steel deck is used as a force-bearing member, the quality defects may have an impact on the structural safety. Therefore, strict inspections are carried out for each process to ensure the quality of each batch of goods. quality assurance;

Various Types of Processing Capabilities

SOLIDECK has more than 30 production lines, which can not only process various types of steel decks, but also customize products according to customer needs to meet the different needs of each customer.

Simple, Easy & Fast

We have a successful track record. We ensure that all projects are executed with the utmost professionalism using quality materials, while providing the support and accessibility you need. We offer pick up within a week, different metal decking always has raw material in stock and different shipments are sent to your job site or location every week. Solideck is located in Shanghai, the economic capital of China, where shipping becomes profitable, internationalization is strong, and efficiency is high

Altruism to service

It is not enough to have good quality and superb technology. Solideck makes better altruistic services to customers, thinks what customers think, how it is beneficial to customers, and can reduce customer costs. Solideck’s advantages are also these. Over the years, customers have been patronizing Solideck for a reason.

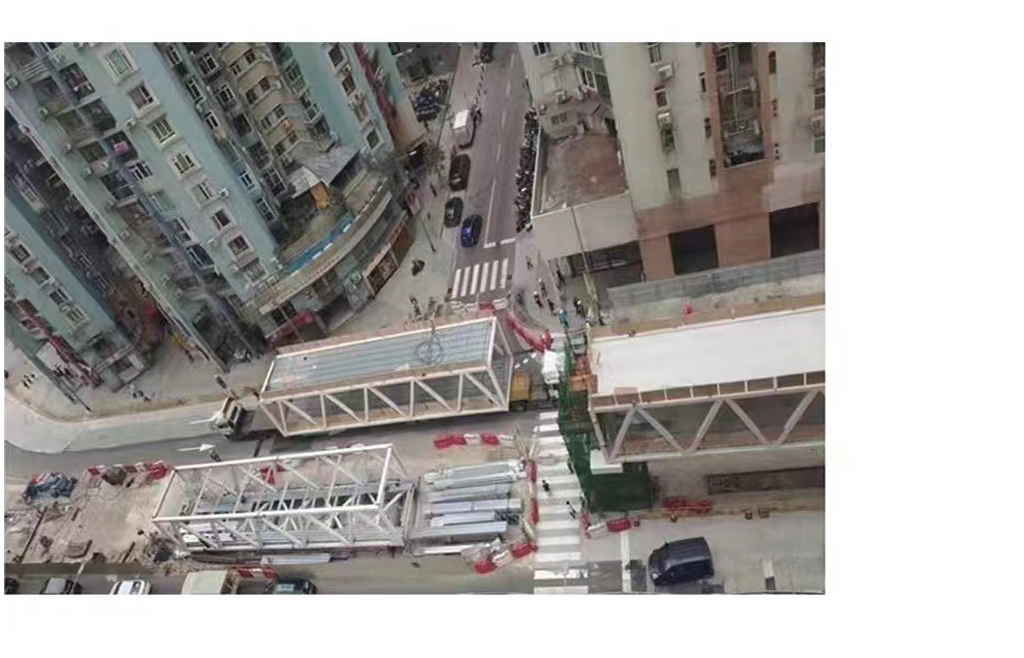

Case Show

Clearance Building

NEWS & EVENT

SOLIDECK has more than 30 production lines, which can not only process various types of steel decks, but also customize products according to customer needs to meet the different needs of each customer.

Steel decks are different from metal decks

First of all, the steel deck is a type of metal deck. Metal decks include many types: steel decks, aluminum decks, copper decks and more. The main metal material for steel decks is steel, while there are many metal materials for metal decks.

Steel decks are mostly used in steel structure buildings, including floor panels, roof panels and wall panels. And it plays the role of formwork in the floor slab, and even plays the role of stressed steel bar. Roof panels and wall panels mainly play the role of enclosure, and the requirements for anti-corrosion will be relatively high. In addition to the steel deck, the metal deck should be selected according to the requirements of the building for metal materials. For example, the wall and roof enclosure system may require anti-corrosion, so the steel deck or aluminum deck with a certain anti-corrosion effect will be selected; the curved surface structure is The ductility of the material is required, so the aluminum deck will be selected; for buildings with high corrosion resistance, the copper deck will be selected.

In terms of forming machines, steel deck forming machines have higher power requirements, but not too high a forming effect; while aluminum decks have lower power requirements for forming machines, and pay more attention to forming effects. Due to the strong hardness of the material itself, the copper deck has high power requirements for the forming machine.

In comparison, the cost of steel decks is the lowest, and the cost of aluminum decks and copper decks will be much higher. Therefore, steel decks are more widely used, while other metal decks are used less

Packaging of steel decks for overseas projects

With the expansion of Solideck in the overseas steel deck market, we have determined different solutions according to different situations regarding the issues that need to be paid attention to in the packaging and transportation of steel decks.

1. About the form of the steel deck transportation

There are two options, cabinet and bulk. For YXB53-600 steel decks, which are partial “thrown” products, cabinet installation is obviously not cost-effective. According to our experience, a 40-foot high cabinet has a loading capacity of about 700-1200 square meters. This is still based on pressure. When the size of the steel plate is relatively consistent, it is estimated that there are at least 20 cabinets for a quantity of 25,000 square meters, and there is no doubt that bulk can often hold more.

2. Protection against product corrosion

Seawater has a great influence on metal corrosion, so anti-corrosion measures must be prepared.Regarding the problem of metal decks corrosion during sea transportation, our company believes that there is little difference in the corrosion of metal decks in cabinets and in bulk. The moisture of sea water has a certain corrosion on the product, which is formed by long-term action. If it is said that the sea voyage is less than two months or less, the impact is minimal, and it is the air (moisture) that affects the product. Corrosion, the effect is not much different in the cabinet and exposed outside, in order to prevent rainwater infiltration during transportation, covering the bulk metal decks with tarpaulin can solve this problem.

3. Collisions and scratches on the metal decks

Another advantage of cabinet packaging is that it is not easy to be hit or scratched by hard objects, which will damage the zinc layer, while bulk packaging is facing collisions and scratches from other goods. Therefore, a protective frame can be built outside the metal decks to prevent the product from being damaged. It is also wrapped with soft cloth or kraft paper to reduce bumps under certain circumstances.

4. Secondary transportation of products

The cabinets are definitely well protected in containers, but they also face the problem of secondary transportation and dragging, which requires a trailer to handle, and there is a risk of scratching the products when dragging them out of the cabinets. In bulk, due to the protective frame, it is rarely damaged even when being dragged, and it can be lifted directly by a crane, which is more convenient for secondary transportation and loading and unloading.

5.The specific method of bulk

- After the profiled steel plates are formed, stack them and pack them with packing belts or steel belts. The weight of each bundle is not more than 3t, and the quantity is not more than 30 pieces. Wooden boards or foam board spacers are required for bundling;

- Mark each bundle of the profiled steel plates, such as customer name, quantity, plate type, thickness, length, application position, etc., and ensure at least 2 marks for each bundle;

- Use channel steel to make the shipping rack, put the bundled profiled steel plates into the shipping rack, and let the rear upper part be blocked with channel steel to form a whole;

- The upper part is covered with tarpaulin to prevent rain, and the logo is made on the outside, and the logo is also made of rainproof treatment.

Picture demo:

- Packaging selection

The packaging plan is determined according to the length and shape of the profiled steel plates. Angle steel channel steel rods can be used to determine the specific drag frame, and it is also determined according to the customer’s budget and requirements.