Phone: 8613421351153

How to fit pour stop

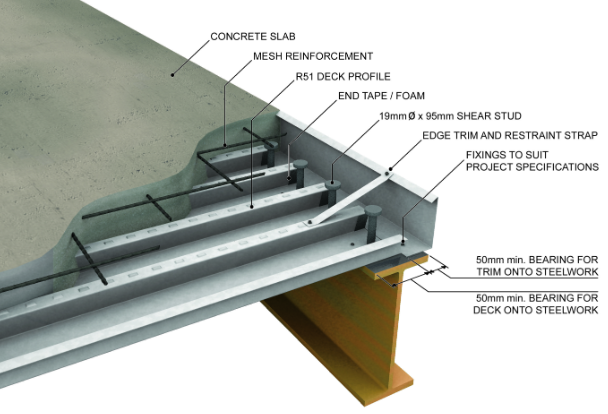

Pour stop is a simple L-shaped section that simplified the installation of most floor slabs.

What is the Pour Stop

Pour stop is used to control the concrete that’s being poured on top of the steel floor deck. The pour stop is made from angle iron or bent plate. It will contain the concrete when you pour a slab that’s greater than the depth of the steel floor deck.The yield strength of pour stop is generally above 33 Ksi, and the thickness is 1.5 mm-3.0 mm.

How to fit Pour Stop

- It is easily fastened to the metal floor deck, neatly retaining the concrete and providing a smooth top edge for quick and accurate screeding. We make it to suit any slab thickness.

- Pour stop is easily spliced and bent to form internal and external corners of any angle and shall be fitted and fully fastened as the sheets are installed. There are various methods of forming corners and splices.

- Fasten Pour stop to the underside of unsupported steel deck very 300mm. The top flange of Pour stop shall be tied to the ribs every 600mm (or less if aesthetics are required) with straps formed on –site using builder’s strapping 25mm x 1.0mm. Use 10-16 x 16mm self –drilling screws.

- Make sure that the zinc coating on Pour stop matches the corrosion protection requirements of your job.

When we understand the Pour Stop of metal floor deck installation method, we can operate it.