Phone: 8613421351153

Steel deck has many accessories used in various steel deck types, including: Pour Stop; End closure; Studs; Screws. Depending on the working conditions or different types of panels, the required accessories are different.

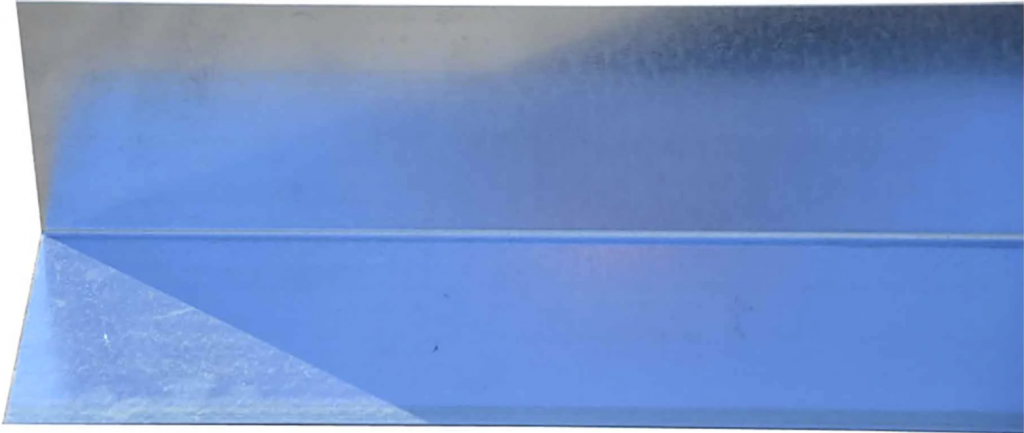

Pour Stop

Pour stop is used to control the concrete that’s being poured on top of the steel floor deck. The pour stop is made from angle iron or bent plate. It will contain the concrete when you pour a composite slab that’s greater than the depth of the steel floor deck.The yield strength of pour stop is generally above 33 Ksi, and the thickness is 1.5 mm-3.0 mm.

End closures

An end closure, also known as a cell closure, is fastened to the end or flutes of the steel floor deck. The end closure prevents the pour of wet concrete from rolling inside the end flutes and down the area below. End closures are a vital component of steel deck installation and make concrete pours quicker and cleaner.

End closure has different shapes according to different types of steel floor decks, and is divided into metal and foam closures according to the material, and metal closure is divided into split type and integral type. The End closure of each manufacturer of the same steel floor deck is also different, customers can inquire when choosing a steel floor deck manufacturer.

Studs

Weld studs and fasteners for capacitor discharge (CD) and drawn arc (DA) stud welding processes.

Weld studs are generally used in composite floor decks, which are welded to steel beams for shear resistance, or used in composite beams to make the performance of composite floor decks more efficient. Used in the metal floor deck, the general studs need to weld the metal floor deck and the steel beam into one. The diameter of Weld studs is 13 mm, 16 mm, 19 mm, 22 mm, generally 16 mm and 19 mm for metal floor deck. The length of Weld studs is determined according to the thickness of composite slab and the height of metal floor deck.